Tips for Selecting the Best Self-Contained Mobile Dental Delivery Unit for In-Office Use

Updated on 12/14/20, 2/7/24

Choosing the right mobile dental unit that aligns with your specific requirements and budget can seem daunting, whether it is for in-office use or for taking out of the office for portable dentistry. Prices of self-contained dental units can vary widely, and the quality and features of these units may contribute to the price differences. When considering purchasing a portable dental unit, it is essential to carefully evaluate numerous factors to ensure that you are getting a reliable and functional product. The purpose of this article is to help you make a well-informed decision, explain essential mechanical features of mobile dental equipment, and outline what to look for when comparing/reviewing different models for your office.

Tip #1 – Evaluate for Minimal Vibration

One of the most overlooked but significant characteristics of evaluating a mobile dental unit is vibration. An ideal system will have a powerful compressor and vacuum system, meaning the motors could generate enough shaking to cause sound and make the work surface unusable if the instruments and trays vibrate excessively. A well-designed unit will ensure that the vibration is minimal to allow dental procedures and working from trays without interruption.

![]()

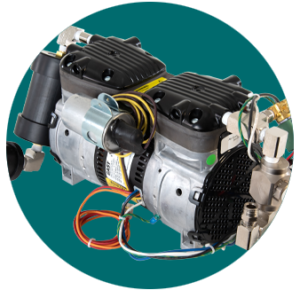

Tip #2 Insist on High Grade Portable Dental Compressor and Vacuum Pumps

Tip #2 Insist on High Grade Portable Dental Compressor and Vacuum Pumps

Greater precision comes with higher quality pumps. The dynamic balancing of the motors and piston will make them run smoother. This smoother operation is the key to beginning with proper construction to eliminate vibration at its source. Higher grade also means that pumps are built to last ten years of use or more and provide a clean oil-less air supply for dental treatment.

![]()

Tip #3 Engineered Isolation Mounts Make a Big Difference

The best way to mount pumps requires not only a stable and secure connection to keep the pumps from moving around but also the need to eliminate transfer of vibration from the pumps to the chassis. Rubber mounts do a fine job of securing the pump but don’t do very well at absorbing vibration. Improved dynamic mounting is of higher quality and eliminates a high percentage of vibration.

Tip #4 Ensure Solid and Robust Construction Materials Are Used

Mobile dental equipment that has poor construction or uses flimsy materials will not handle vibration well and will cause problems. A well-built portable dental unit will be not only constructed of high-grade components but will also have thicker walls and materials. Units should use aluminum or an equivalent type of construction to keep them lighter yet stronger. To properly absorb vibration, be cautious of dental units that are too small or lightweight.

![]()

Tip #5 Verify Sound Performance with Your Own Ears

Tip #5 Verify Sound Performance with Your Own Ears

Well known options in the dental field are the inexpensive, poorly designed, and loud portable dental units A well-engineered self-contained dental unit should be quiet and operate under 48 decibels measured right next to the system. However, sound can be elusive, and decibels do not always truly represent sound. There is no standardized testing certification used to compare brands to the sound levels they claim. So, the best way to find out the sound of the system would be to hear it in person. If that is not practical, then either listen to a video of the operating system or get a recommendation from someone you trust that has heard the systems.

![]()

Tip #6 Determine if Suction Performance is Powerful

One of the most challenging design areas for a mobile dental unit is to create the powerful suction desired for dental procedures. It needs to provide high flow with moderate strength to pick up debris, effectively capture water coolant, and pull viscous solutions through smaller tubings like the saliva ejector or surgical tips. To adequately perform dental restorative procedures, the system should be able to power the high-volume suction and be able to extract liquid through the saliva ejector simultaneously. When comparing portable dental units with compressors, evaluate the suction strength of both the high volume and saliva ejector handpieces when used together so that you know if you have a well-designed portable dental suction system. A dedicated vacuum built into the unit for strong suction capability or even high-flow vacuum options are, in many cases, an ideal solution.

Tip #7 Verify Adequate Suction Canister Size

The size of the suction canister should allow for a standard day of dental procedures with regular oral rinsing during treatment. A general baseline is that the canister should hold around two liters of liquid. The canister should prevent overflowing by shutting off the vacuum when full and should have an indicator light to let staff know to empty the system.

![]()

Tip #8 Consider Suction Canister Purging Ability

Tip #8 Consider Suction Canister Purging Ability

Consider a hands-free solution to emptying the contents of the suction canister through a pump and discharge hose system. Use a purge system to discharge directly into a sink basin or a convenient quick disconnect connected to the plumbing drain system. Once emptied, readily rinse the system by evacuating clean water and then clean overnight by suctioning an enzymatic cleaner that breaks down the proteins in blood and saliva.

![]()

Tip #9 Check for Adequate Compressed Air and Handpiece Performance

When evaluating a portable dental unit with a built-in air compressor, make sure that it can produce enough airflow at the right pressure to operate air-driven dental turbine handpieces properly. Don’t be tricked into using horsepower to try and compare models. Unfortunately, horsepower ratings have a wide range of latitude, and marketing companies have used the HP rating to trick many consumers into believing one model has more power than another. Find out if the system you are evaluating can adequately run common brands of dental turbine handpieces for an extended period without pressure dropping.

Tip #10 Make Sure Aesthetics are Professional and It is Easy to Work with the System

It is necessary for the system you will be using to look like a professional piece of dental equipment that delivers high-quality care since it is in an office setting. Look for systems that have enclosures made of quality materials and finished in a way that looks modern with rounded corners and edges. Work surfaces should provide an adequate working area and provide an easy to clean, attractive appearance. As a mobile dental cart, it should roll easily with high-grade casters. Other considerations are ensuring that the dental unit has cling free dental handpiece tubing that is not stiff and that handpiece holders should be modern, rounded, and easy to clean.

![]()

Tip #11 Uses Standard Electrical Outlets

Tip #11 Uses Standard Electrical Outlets

A well-designed self-contained dental unit should be able to operate from a standard electrical outlet without overloading the circuit even with both pumps running at the same time.

![]()

Tip #12 Has Required Safety Testing Lab Approval

Ensure that the model you select has a UL certification by an approved testing lab. Knowing that all the electrical components, wiring, switches are high quality assembled correctly will give you peace of mind and ensure your office meets building code requirements.

Tip #13 Includes Adequate Dental Water Supply and Water Line Disinfection

Current requirements are mandating the disinfection of the water lines in a dental unit to remove the biofilm that can grow inside the small diameter tubings. Tablets and other chemicals can clog or damage mobile dental equipment components and require consistent management to ensure the removal of biofilm. An ideal self-contained dental unit should have a water line disinfection cartridge that can be part of the bottle system so that no daily maintenance is required. Since these cartridges can be expensive, select a system with a tandem water supply that gives ample water supply for a full day of dental procedures but only requires one cartridge to filter both bottles.

![]()

Tip #14 Has Amalgam Separation Option

Tip #14 Has Amalgam Separation Option

If you are using the portable dental unit for restorative procedures such as removing old amalgam fillings, the suction system will need the ability to use an amalgam separator. The unit can purge through the amalgam separator to collect the heavy metals. The amalgam separator must receive testing and approval by a certifying agency to meet state and EPA regulations. Verify that the model you use provides a certified separator option.

![]()

Tip #15 Can Handle Nitrous Oxide Scavenging

In-office use of a self-contained dental unit will often require the ability to use the portable dental suction to connect to the nitrous patient mask to scavenge off the excess gas. Check to ensure that the portable dental system has the optional capability to be used for nitrous exhaust scavenging.

Please visit our Portable Performance Page on ASI Dental’s line of advanced mobile dental delivery system technology to evaluate the features a well-built system can have. For a complete selection of portable dental equipment, go to ASIDental/products/portable.

Copyright 2020 and 2024 All Rights Reserved. ASI Medical, Inc. DBA ASI Dental Specialties | Terms & Conditions of Use